This article is an excerpt from the Shortform book guide to "The Goal: A Process of Ongoing Improvement" by Eliyahu M. Goldratt. Shortform has the world's best summaries and analyses of books you should be reading.

Like this article? Sign up for a free trial here .

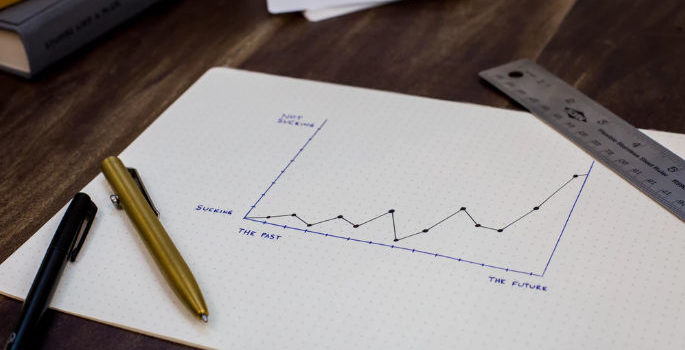

How can you increase capacity in manufacturing? Why is it important to increase capacity at your bottlenecks?

The Goal is all about improving your production output. One key way to do this is by implementing strategies to increase capacity where you have a bottleneck.

Keep reading for more about how to increase capacity in production and improve output overall.

Increase Capacity at the Bottleneck

The protagonist of The Goal book undergoes multiple iterations of increasing capacity as his bottleneck to increase overall throughput. Without detailing every struggle, in this book summary we’ll cover common causes of reduced capacity at bottlenecks, and fixes to increase capacity.

(Shortform note: This is a good point to consider your own work or life in this context, and to construct effective ways to relieve your personal bottlenecks.)

Fixes to Bottlenecks Can Increase Capacity

We can divide this into a few themes.

Improve the Bottleneck Itself

- Skip unnecessary steps or decreasing setup/switching costs.

- Add on supplements to increase bottleneck capacity, even if they’re less efficient

- Guarantee round-the-clock production at the bottleneck.

- Example: Eliminate lunch breaks and downtime.

- Permanently staff people at bottlenecks to decrease idle time.

- Eg have people waiting by dishwasher to prepare loads and unload immediately.

- Remember that the cost of a lost hour at this bottleneck is very expensive, and possibly well worth people idling on standby.

Improve What the Bottleneck is Working On

- Focus the bottleneck only on parts that are needed today, not for safety’s sake tomorrow.

- Order the work in terms of first in, first out – clear the backlog first to guarantee important work is being done.

- Allow parts to skip the bottleneck step if it’s not necessary.

- Collect accurate statistics on bottleneck operations to make better decisions.

Optimize the System for the Bottleneck

- Redistribute capacity from non-bottlenecks to the bottleneck (e.g. more workers).

- Make sure there is extra inventory ahead of the bottleneck so it can always be running at full capacity.

- Take some of the load on the bottleneck and redistribute to non-bottlenecks, if the same function can be performed.

- Do quality control upstream of the bottleneck to prevent time processing substandard parts.

- Tag parts that will go to the bottleneck as higher priority, so they get processed first and you guarantee inventory in front of the bottleneck. The bottleneck gets an express lane.

- Announce the importance of bottleneck to the entire team, so they understand the priority of processing for the bottleneck.

- Check upstream steps to see if adjustments can be made that decrease load on bottleneck.

- In The Goal, the team discovers that running an upstream milling step more efficiently leads to requiring heat treatment. If this is slowed down, then the parts can skip heat treatment. In this case, lowering efficiency at one step actually increases throughput.

- Outsource the bottleneck outside the organization.

(Shortform suggestion: take some time to consider how to apply these to your own life. For example, say you’re a manager who wants to improve your throughput. Consider the above fixes directly applied to a manager, whose time can often be the bottleneck of an organization’s throughput:

- Increase your time on tasks that you are uniquely good at (ideally, these are higher leverage tasks). Train others to take over your lower level responsibilities.

- Allow workers to bypass you for permission for smaller decisions. Don’t require everything to pass by your desk.

- Prevent idle time by enforcing meetings starting on time with everyone present.

- Track your backlog so that more important items are worked on first, then process in first-in first-out order.)

Market Demand and Throughput

Ideally, the flow through the bottleneck should match market demand. Producing more than this will increase inventory of finished product. Too much inventory will hinder flexibility through sunk cost fallacy – you’ll be reluctant to adapt to new market demands, because it would mean writing down your old inventory.

Instead, when you have surplus capacity, try to increase sales to make use of this capacity. Because you’re already paying for the fixed costs, you can lower prices to above material (marginal) cost to simulate more demand. This will decrease your overall cost per product.

Shortform Exclusive: Applications to Non-Manufacturing Work

While The Goal is literally concerned with manufacturing, its principles are generalizable to any work system in which multiple parts contribute to a single goal.

Consider asking yourself these questions:

- Are you refusing profitable work because you don’t have enough throughput? If so, find your bottleneck and alleviate it.

- How can you cut batch size to increase efficiency?

- Where is the weakest link in your chain?

- Are you currently the bottleneck for any throughput? How can you tell?

- What are 3 ways you can relieve yourself as the bottleneck?

———End of Preview———

Like what you just read? Read the rest of the world's best book summary and analysis of Eliyahu M. Goldratt's "The Goal: A Process of Ongoing Improvement" at Shortform .

Here's what you'll find in our full The Goal: A Process of Ongoing Improvement summary :

- How to increase your personal output

- How to increase your team's output

- Why obsessing over cost efficiency isn't going to help you with production