This article is an excerpt from the Shortform book guide to "High Output Management" by Andrew S. Grove. Shortform has the world's best summaries and analyses of books you should be reading.

Like this article? Sign up for a free trial here .

What does build to forecast mean? How does it help with productivity?

Build to forecast is one productivity strategy where manufacturers predict how many items they’re going to need, and build enough to satisfy demand. This is usually a reliable productivity strategy.

Keep reading to find how how to build to forecast.

Build to Forecast

The second strategy is building to forecast, in which manufacturers (or managers) predict how many orders they’re going to get for each product and build enough to satisfy them. The advantage of build to forecast is that customers don’t have to wait for products. (If manufacturers waited until they had orders to start building—referred to as the “build to order” method—customers would have to wait longer for their products.)

- Manufacturing example: Intel builds computer parts to forecast this because their throughput times are long and customers don’t want to wait for products.

- Business example: As a manager, you can use your calendar to help you forecast demands on your time and how you’ll schedule them. The limiting step (the step that takes the longest or is most important) is scheduled firmly and the non-time-sensitive ones can offset where there’s space.

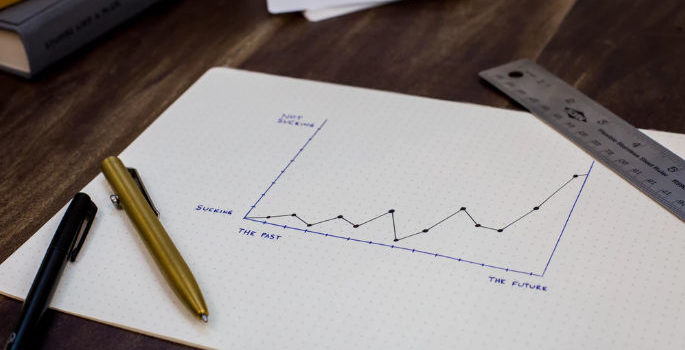

Both sales and manufacturing forecast so that both departments are accountable for meeting their predictions, and they use stagger charts to help with accuracy.

The disadvantage of building to forecast is that if the predictions are wrong, manufacturers end up with a bunch of leftover inventory or lack the inventory customers do want. However, this is still preferable to making customers wait.

Delivering built-to-forecast products involves two simultaneous processes with their own timelines. Ideally, both flows finish at the same time:

- Manufacturing flow, which involves getting the raw materials through production, to being finished goods, to the shipping dock.

- Sales flow, which involves finding customers, selling them the product, securing an order, and then shipping it.

However much you plan, it’s rare that the two flows line up exactly—sometimes, customers change their minds or there’s a mistake in the manufacturing process—which is where the slack (extra time or resources) you left in the system will come in handy.

Some businesses use both building to order and building to forecast—for example, the breakfast cafe builds breakfast to order (cooks only start cooking after a customer has ordered) but buys raw inventory (purchases eggs, toast, and coffee) based on forecasted demand because it’s not possible to acquire it instantly.

———End of Preview———

Like what you just read? Read the rest of the world's best book summary and analysis of Andrew S. Grove's "High Output Management" at Shortform .

Here's what you'll find in our full High Output Management summary :

- How to increase your managerial output and productivity

- The 11 activities that offer a higher impact on output

- How meetings can be used as a time management tool